ISA Gear Standards

The Safety Commission has developed gear standards for slacklining equipment. The standards are a description of tests the equipment has to pass to get the Label. The Label is printed on the manual, manufacturer’s website and the product itself.

This is what the ISA Safety Label looks like:

What does it mean?

The ISA Safety Label shows that every batch of equipment has successfully passed a series of tests designed to ensure the product’s safety and longevity. These tests check if the product is suitable for highlining.

Why?

The Label ensures a minimum safety standard for slackline equipment. It supports the manufacturers who guarantee the safety of their gear and give them an opportunity to advertise this in a transparent way. Standardized tests let slackliners make informed decisions by allowing them to compare across brands (before the numbers didn’t mean the same thing for different manufacturers).

How is equipment tested?

Testing facilities

Equipment is sent to an ISA approved, independent testing facility. This means not the ISA tests the gear, but seperate facilities. Gear manufacturers therefore have to pay these facilities and NOT the ISA to get their gear tested.

The ISA Safety Commission is currently looking for more independent inspection bodies across the world to lower shipping time and costs.

In addition to this one-time certification, the Safety Commission will regularly perform their own secret tests of certified and uncertified gear at their own cost as a form of quality control for the slackline market.

Webbing Lockers

Weblocks have to pass 4 different tests. The first one checks the overall quality – edges, pins and markings. The second checks if you have working way of tieing of your weblock against slippage. The third test checks the weblock’s ability to retain webbing strength. Finally – a break test, to check the weblock’s ultimate strength with a seewn hightech webbing loop. Only weblocks with an MBS of 48 kN or more can pass.

Webbing

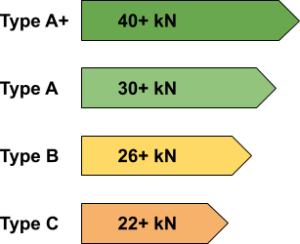

Webbing is categorized into 4 different types with different MBS, abrasion resistance and lifetime. Lifetime is counted as days exposed to the elements. Leaving your line rigged for a week costs 7 days of lifetime (regardless of use, because UV is the main culprit). Webbing will come with a small tag to help you keep track of how many days of highlining it has seen. Webbing lifetime is finite – once the days run out it is no longer safe for highlining. Webbing can become unsafe much earlier for other reasons – abrasion, excessive use and harsh conditions can all lead to an early retirement (consider making a slack rag).

Type A+ is the super webbing with more than 40 kN MBS and a very long lifetime. Recommended for permarigs.

Type A webbing can be used in all kinds of highline situations. It has an MBS of 30 kN or more.

Type B webbing is for alpine missions and those of you who don’t like heavy backpacks. With a 26 kN MBS it can be used (with caution) on most highlines.

Type C has significantly shorter lifetime and abrasion resistance. With an even lower MBS of 22 kN, it should only be used by experienced riggers and in controlled circumstances (competitions, shows, birthday parties, etc.).

All types of sewn loops are also tested. They have to retain 80% of the MBS of their category. (E.g. Type A: 30kN minimum → All Type A loops have min. 80% x 30kN = 24kN)

Every webbing will have a standardized stretch curve, measured at the same speed, and the stretch % at 5 kN has to be stated in the manual. Why 5 kN? Because the traditional 10 kN does not reflect the forces in real life usage.

| Strength class | PA (nylon) | PES (polyester) | High-Tech | All other |

|---|---|---|---|---|

| Type C (22+ kN) | 180 days | Not certified as single webbings | Not certified as single webbings | Not certified as single webbings |

| Type B (26+ kN) | 360 days | 360 days | Not certified as single webbings | 360 days |

| Type A (30+ kN) | 720 days | Optical/haptical inspection | 720 days | 720 days |

| Type A+ (40+ kN) | 720 days | Optical/haptical inspection | 1440 days | 1440 days |

Leash

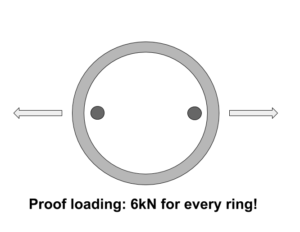

A leash consists of a tether and rings. There can be either one or two rings, with a combined MBS of 24 kN. Each ring set has to be individually proof-loaded by the manufacturer to 6 kN. It is also time to say goodbye to the classic BOMBER rings, as there is now a 150 g weight limit, because teeth replacement is too expensive. Thimbles, splices and sewn terminations are also tested and they have to hold a minimum of 15 kN, just like your harness! The rope itself needs to be a certified dynamic or static climbing rope with a minimum diameter of 9mm (thinner ropes can break or cut limbs and fingers when accidentally wrapped around during a leashfall).

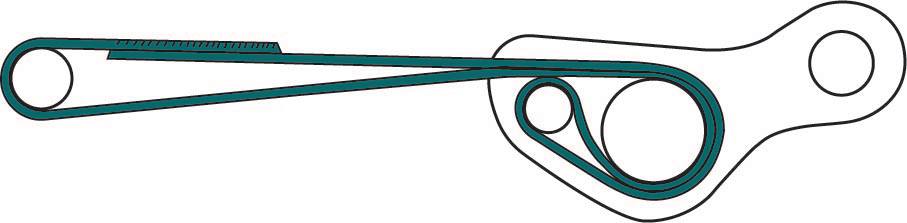

Webbing Grab

Webbing grabs are not staying in the system and therefore are not safety critical. They only have to pass one test, to make sure they don’t slip. Don’t load them above the indicated WLL and be especially careful in hot and cold weather conditions!

Buy the ISA gear standards

Here you can order the ISA gear standards.

The first ISA standard (ISA:21 Highline System) is free.

It defines a highline system, its components, dimensions and loads and refers to the other ISA standards